NEBCO™ STYLE 702 AKⅡ®

-

Description

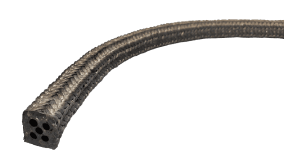

NEBCO™ Style 702 AKⅡ® is manufactured from a continuous filament graphite yarn with a break-in lubricant and graphite. This style can provide rapid heat dissipation in rotating service. This heat transferability coupled with the chemical resistance of this yarn and our unique ANTI-KEYSTONE® Ⅱ packing technology, creates a long-lived compliant packing that can be used in all but the most severe corrosive service.

NEBCO™ Style 702 AKⅡ® is manufactured from a continuous filament graphite yarn with a break-in lubricant and graphite. This style can provide rapid heat dissipation in rotating service. This heat transferability coupled with the chemical resistance of this yarn and our unique ANTI-KEYSTONE® Ⅱ packing technology, creates a long-lived compliant packing that can be used in all but the most severe corrosive service.

Style 702 AKⅡ® may be run “flush free” in certain applications without any cooling water thus eliminating the lantern ring. Running “flush free” means fewer gland adjustments further reducing your operational cost. Using this style as a bottom anti-extrusion device with Style 7800 AKⅡ® is the ultimate combination set for rotating equipment when “flush free” service is attempted.

-

Specifications

- pH range: 0-14 (except strong oxidizers).

- Surface speeds to: 5,100 FPM (25.9 m/s).

- Pressure to: 3,000 PSI (206 bar).

- Temperatures from: -400°F (-240°C) to 800°F (426°C).

- Abrasion resistant.

- Extrusion resistant.

- Excellent heat transfer.

- Flush free capabilities.

- Continuous filament graphite yarn.

-

Applications & Services

APPLICATIONS: Include use in most rotating equipment such as agitators & mixers, pump and valve applications, especially high speed & high temperature. This style is can be used as a bullring or anti-extrusion device in abrasive service.

SERVICES: Include acids, bases, oils, solvents, and water-based solutions.

*Style 702 AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 702 AF AKⅡ® CHEMSTOP™ VIBRADAMP®

-

Description

NEBCO™ Style 702 AF AKⅡ® Chemstop™ Vibradamp® is the chemically resilient core version of our Style 702. It is manufactured from a continuous filament graphite yarn with a break-in lubricant and graphite, with strategically placed AFLAS® cores.

NEBCO™ Style 702 AF AKⅡ® Chemstop™ Vibradamp® is the chemically resilient core version of our Style 702. It is manufactured from a continuous filament graphite yarn with a break-in lubricant and graphite, with strategically placed AFLAS® cores.

The resilient elastomeric cores and our densely braided ANTI-KEYSTONE® Ⅱ design can help reduce the leakage and gland adjustments where shafts on pumps and other equipment are out-of-round, vibrate, or are subject to impact.

Style 702 AF AKⅡ® may only be run “flush free” if certain conditions are met & within its specifications.

AFLAS® is a registered trademark of Asahi Glass Co., Ltd.

-

Specifications

- pH range: 1-13 (except strong oxidizers).

- Surface speeds to: 5,100 FPM (25.9 m/s).

- Pressure to: 3,000 PSI (206 bar).

- Temperatures from: -65°F (-53°C) to 400°F (204°C).

- Abrasion resistant.

- Extrusion resistant.

- Chemical resistant rubber cores.

- Continuous filament graphite yarn.

-

Applications & Services

APPLICATIONS: Include use in most rotating equipment such as agitators & mixers, pump and valve applications. Style 702 AF AKⅡ® is appropriate as a bullring or anti-extrusion device in abrasive service.

SERVICES: Include acids, bases, oils, solvents, and water-based solutions.

*Style 702 AF AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 728 AKⅡ®

-

Description

NEBCO™ Style 728 AKⅡ® is manufactured from high purity exfoliated graphite yarn with no fillers or binders. This style is a self-lubricating packing that can help extend the shaft or sleeve life.

NEBCO™ Style 728 AKⅡ® is manufactured from high purity exfoliated graphite yarn with no fillers or binders. This style is a self-lubricating packing that can help extend the shaft or sleeve life.

It has excellent heat transfer capabilities and may be run dry or “flush free” in certain applications without any cooling water thus eliminating the lantern ring. Dry running means fewer gland adjustments further reducing your operational cost. -

Specifications

- pH range: 0-14 (except strong oxidizers).

- Surface speeds to: 4,200 FPM (21.3 m/s).

- Pressure to: 5,000 PSI (344 bar).

- Temperatures from: Mild oxidizers to 1,800°F (982.2°C).

Non-oxidizers to 5000°F (2760°C). - Excellent heat transfer.

- Flush free capabilities.

- Exfoliated graphite yarn.

-

Applications & Services

APPLICATIONS: Includes use in most rotating equipment, pump and valve applications, especially high speed and high temperature. Also applicable for sealing mixers and agitators, centrifugal pumps and reciprocating equipment.

SERVICES: Includes acids, bases, oils, solvents, and water-based solutions.

*Style 728 AKII® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 7800 AKⅡ®

-

Description

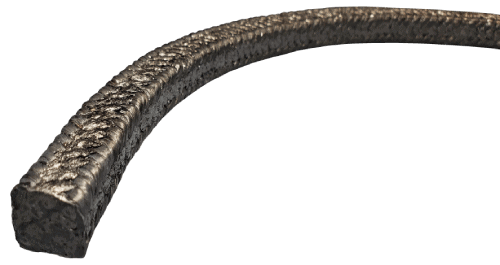

NEBCO™ Style 7800 AKⅡ® is one packing that is nearly universal. Manufactured from exfoliated graphite with continuous filament graphite yarn used on the corners for extrusion resistance. This style is a self-lubricating packing that can help extend the shaft or sleeve life. It is made with no fillers or binders.

NEBCO™ Style 7800 AKⅡ® is one packing that is nearly universal. Manufactured from exfoliated graphite with continuous filament graphite yarn used on the corners for extrusion resistance. This style is a self-lubricating packing that can help extend the shaft or sleeve life. It is made with no fillers or binders.

This packing provides rapid heat dissipation in rotating service, while its conformability reduces inter-ring product entrapment in valves. Because of its rapid heat dissipation, Style 7800 AKⅡ® can run “flush free” in certain applications without any cooling water thus eliminating the lantern ring. Running “flush free” means fewer gland adjustments further reducing your operational cost.

-

Specifications

- pH range: 0-14 (except strong oxidizers).

- Surface speeds to: 5,100 FPM (25.9 m/s).

- Pressure to: 5,000 PSI (344 bar).

- Temperatures to: Steam to 1,800°F (982°C).

Non-oxidizers to 5,000°F (2,760°C). - Excellent heat transfer.

- Exfoliated graphite base material.

- Continuous filament graphite yarn reinforced corners.

- pH range: 0-14 (except strong oxidizers).

-

Applications & Services

APPLICATIONS: Ideally suited for boiler feed pumps, condensate pumps, refiners, agitators, mixers & hydropulpers. In addition, vacuum pumps, fire pumps, fly-ash pumps & soot blowers.

SERVICES: This style is applicable for use in most services including steam, acids, bases, oils, solvents and water-based solutions.

* Style 7800 AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 7800 SC AKⅡ® VIBRADAMP®

-

Description

NEBCO™ Style 7800 SC AKⅡ® Vibradamp® is the resilient core version of our Style 7800. It is manufactured from exfoliated graphite with continuous filament graphite yarn used on the corners for extrusion resistance with strategically placed silicone cores. This style is a self-lubricating packing that can help extend the shaft or sleeve life. It is made with no fillers or binders.

NEBCO™ Style 7800 SC AKⅡ® Vibradamp® is the resilient core version of our Style 7800. It is manufactured from exfoliated graphite with continuous filament graphite yarn used on the corners for extrusion resistance with strategically placed silicone cores. This style is a self-lubricating packing that can help extend the shaft or sleeve life. It is made with no fillers or binders.

The resilient elastomeric cores and our densely braided ANTI-KEYSTONE® Ⅱ design can help reduce the leakage and gland adjustments where shafts on pumps and other equipment are out-of-round, vibrate or are subject to impact.

Style 7800 SC AKⅡ® may only be run “flush free” if certain conditions are met & within its specifications.

-

Specifications

- pH range: 3-11 (except strong oxidizers).

- Surface speeds to: 5,100 FPM (25.9 m/s).

- Pressure to: 5,000 PSI (344 bar).

- Temperatures to: -40°F (-40°C) to 400°F (204°C).

- Exfoliated graphite base material.

- Continuous filament graphite yarn reinforced corners.

-

Applications & Services

APPLICATIONS: Ideally suited for boiler feed pumps, condensate pumps, refiners, agitators, mixers & hydropulpers. In addition, vacuum pumps, fire pumps, fly-ash pumps & soot blowers.

SERVICES: Applicable for use in most services including acids, bases, oils, solvents and water-based solutions.

*Style 7800 SC AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

Disclaimer

*Certain styles & sizes are special order only and may be subject to minimum quantities and/or additional terms & conditions.

**For informational purposes only. New England Braiding Co., Inc. (NEBCO™) believes this information to be the best available. Any specific application you have should not be undertaken without independent study and evaluation for suitability, safety and material compatibility. No warranty is expressed or implied as each application is unique. While we have used the utmost care in the preparation of this information, we assume no liability for errors or responsibility for consequential damages resulting from the use of these products.