NEBCO™ STYLE 98 AKⅡ®

-

Description

NEBCO™ Style 98 AKⅡ® is manufactured using PTFE filament yarns with PTFE lubricants incorporated into the fibers. PTFE lubricant has one of the lowest friction coefficients for any solid, reducing breakaway friction in valves and increasing packing life.

NEBCO™ Style 98 AKⅡ® is manufactured using PTFE filament yarns with PTFE lubricants incorporated into the fibers. PTFE lubricant has one of the lowest friction coefficients for any solid, reducing breakaway friction in valves and increasing packing life.

This style allows for easy conformance to the valve stem or shaft and is inert in most services and is extremely resistant to penetration by liquids or gasses. It is white, non-staining, dimensionally stable, non-wicking and non-hardening.

Style 98 AKⅡ® meets the required specifications of MIL-P-24396A, Type B (ships). -

Specifications

- pH range: 0-14 (except strong oxidizers).

- Surface speeds to: 700 FPM (3.5 m/s).

- Pressure to: 5,000 PSI (344 bar).

- Temperatures from: -400°F (-240°C) to 500°F (260°C).

- Silicone free.

- Chemically resistant.

- PTFE filament fibers.

-

Applications & Services

APPLICATIONS: Include rising and rotating valve stems, slow speed pump shafts or rods, and mixers. Style 98 AKⅡ® is appropriate for use in chemical plants and in control or ammonia valves in industries such as food and gas processing. This style is highly recommended for acid pumps in all industries such as: phosphate mining, sewerage disposal, power generation, textile finishing and many more.

SERVICES: Include the harshest chemical solutions, steam, solvents, and cooking liquors.

*Style 98 AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 100 AKⅡ®

-

Description

NEBCO™ Style 100 AKⅡ® is a densely constructed compression packing manufactured from braided white PTFE fluorocarbon fibers blended with a small percentage of aramid fiber. This yarn is uniformly impregnated with PTFE suspensoid and treated with an inert lubricant.

NEBCO™ Style 100 AKⅡ® is a densely constructed compression packing manufactured from braided white PTFE fluorocarbon fibers blended with a small percentage of aramid fiber. This yarn is uniformly impregnated with PTFE suspensoid and treated with an inert lubricant.

Initially designed for bleach valves and towers, the chemical inertness provides high speed, non-staining sealing where harsh fluids must be contained. These properties make this style ideal for sealing valves in chemical, agricultural and petroleum processing industries. -

Specifications

- pH range: 0-14 (except strong oxidizers).

- Surface speeds to: 2,000 FPM (10.1 m/s).

- Pressure to: 2,500 PSI (172 bar).

- Temperatures from: -400°F (-240°C) to 500°F (260°C).

- Abrasion resistant.

- Non-staining.

- Non-wicking.

- PTFE fluorocarbon/aramid fibers.

-

Applications & Services

APPLICATIONS: Includes rotating pumps, agitators, and mixers, bleach washers, reciprocating metering pumps, chemical injectors, valves and other equipment handling products. Especially suited for sealing valves & knife gates in chemical, agricultural, petroleum processing and waste water treatment industries.

SERVICES: Includes Sulfate, Sulfite, and NSSC pulping liquors. Air, gasses, oils, solvents, harsh chemicals and paper pulp stocks at any stage and other fluids where contamination may prove a problem.

*Style 100 AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

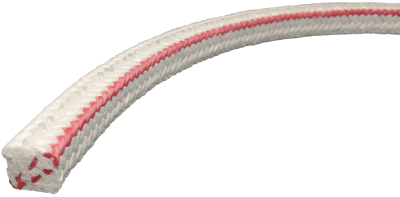

NEBCO™ STYLE 102 AKⅡ® Blackjack® Superpack®

-

Description

NEBCO™ Style 102 AKⅡ® Blackjack® Superpack® packing is manufactured from 100% GORE® GFO® fibers, densely braided using New England Braiding Company’s ANTI-KEYSTONE® Ⅱ packing technology. This style combines the highest temperature and surface speed capability with the broadest chemical resistance of any PTFE fiber-based packing we offer.

Expanded PTFE filaments encapsulate submicron sized graphite particles which provide a graphite running surface after start-up. An inert break-in lubricant reduces burnout in difficult start-up situations. The high heat transfer rates provided by graphite permit running temperatures approaching the physical limits of the PTFE matrix.

With genuine W.L. Gore® fibers and

New England Braiding’s ANTI-KEYSTONE® Ⅱ technology,

Blackjack® Superpack® Style 102 AKⅡ® is a winning combination.

GORE® and GFO® are registered trademarks of W.L. Gore & Associates.

-

Specifications

- pH range: 0-14 (except strong oxidizers).

- Surface speeds to: 4,200 FPM (21.3 m/s).

- Pressure to: 2,000 PSI (137 bar).

- Temperatures from: -400°F (-240°C) to 500°F (260°C).

- Does not harden.

- Easy to install, resists fraying when cut.

- Oriented virgin ePTFE highly infused with ultra-pure graphite powder, with an inert lubricant.

-

Applications & Services

APPLICATIONS: High-speed pumps, valves, mixers, extruders, agitators, blenders, or any other equipment with rotating or reciprocating shafts.

SERVICES: Unbleached paper stocks, water, oils, pulping liquors, acids and bases, and other chemical solutions.

*Style 102 AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

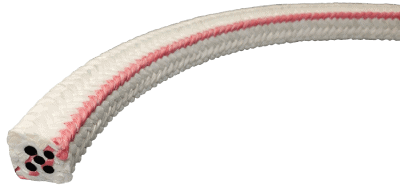

NEBCO™ STYLE 102 SC AKⅡ® BLACKJACK® VIBRADAMP®

-

Description

NEBCO™ Style 102 SC AKⅡ® Blackjack® Vibradamp® is the resilient core version of our Style 102. This packing is manufactured from 100% GORE® GFO® fibers, with strategically placed silicone cores. Expanded PTFE filaments encapsulate submicron sized graphite particles which provide a graphite running surface after start-up. An inert break-in lubricant reduces burnout in difficult start-up situations.

The resilient elastomeric cores with our densely braided ANTI-KEYSTONE® Ⅱ design can help reduce the leakage and gland adjustments where shafts on agitators, hydroturbines, and other equipment are out-of-round, vibrate or subject to impact.

GORE® and GFO® are registered trademarks of W.L. Gore & Associates. -

Specifications

- pH range: 3-11(except strong oxidizers).

- Surface speeds to: 4,200 FPM (21.3 m/s).

- Pressure to: 2,000 PSI (137 bar).

- Temperatures from: -40°F (-40°C) to 400°F (204°C).

- Does not harden.

- Easy to install, resists fraying when cut.

- Oriented virgin ePTFE highly infused with ultra-pure graphite powder, with an inert lubricant.

-

Applications & Services

APPLICATIONS: High-speed pumps, valves, mixers, extruders, agitators, blenders, or any other equipment with rotating or reciprocating shafts.

SERVICES: Unbleached paper stocks, water, oils, pulping liquors, acids and bases, and other chemical solutions.

*Style 102 SC AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 120-P AKⅡ®

-

Description

NEBCO™ Style 120-P AKⅡ® is manufactured from a yarn that is a 100% mix of PTFE fiber and dispersion, which also incorporates a lubricant to resist glazing.

NEBCO™ Style 120-P AKⅡ® is manufactured from a yarn that is a 100% mix of PTFE fiber and dispersion, which also incorporates a lubricant to resist glazing.

This style resists the action of the harsh cleansers, rinses, and even steam used in cleaning food-handling equipment. This leads to a maximum economy in use since this packing can be used for the maximum number of cycles permitted in a given food handling process.

Style 120-P AKⅡ® can be used in the food service and pharmaceuticals industries and in specific applications in other industries. -

Specifications

- pH range: 2-13 (except strong oxidizers).

- Surface speeds to: 1,200 FPM (6 m/s).

- Pressure to: 1,500 PSI (103 bar).

- Temperatures from: -400°F (-240°C) to 500°F (260°C).

- White in color.

- Non-staining.

- PTFE yarn used in Style 120-P complies with Title 21 CFR 177.1550 (Perfluorocarbon resins). The lubricant complies with Title 21 178.3570 for USDA incidental food contact.

-

Applications & Services

APPLICATIONS: Include all food handling equipment with rotating shafts, reciprocating rods, rams, presses, valves and even as a gasket where suitable.

SERVICES: Includes foodstuff of all kinds, potable water, and any process where sanitation is a critical concern. Some of the more common applications can be found in sugar refineries, dairy processing, breweries and distilleries.

*120-P AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 120-PB AKⅡ® VIBRADAMP®

-

Description

NEBCO™ Style 120-PB AKⅡ® Vibradamp® is the resilient core version of our Style 120-P. It is manufactured from a yarn that is a 100% mix of PTFE fiber and dispersion. This style incorporates Buna rubber core material and is non-toxic and non-marking.

NEBCO™ Style 120-PB AKⅡ® Vibradamp® is the resilient core version of our Style 120-P. It is manufactured from a yarn that is a 100% mix of PTFE fiber and dispersion. This style incorporates Buna rubber core material and is non-toxic and non-marking.

The resilient elastomeric cores with our densely braided ANTI-KEYSTONE® Ⅱ design can help reduce the leakage and gland adjustments where shafts are out-of-round, vibrate or subject to impact.

Style 120-PB AKⅡ® Vibradamp® can be used in the food service and pharmaceuticals industries and in specific applications in other industries. -

Specifications

- pH range: 2-13 (except strong oxidizers).

- Surface speeds to: 1,200 FPM (6 m/s).

- Pressure to: 1,500 PSI (103 bar).

- Temperatures from: -65°F (-53°C) to 400°F (204°C).

- White in color.

- Non-staining.

- PTFE yarn used in Style 120-PB complies with Title 21 CFR 177.1550 (Perfluorocarbon resins). The lubricant complies with Title 21 178.3570 (lubricants)for USDA incidental food contact. The Buna cords comply with Title 21 177.2600 (rubber polymers).

-

Applications & Services

APPLICATIONS: Include all food handling equipment with rotating shafts, reciprocating rods, rams, presses, valves and even as a gasket where suitable.

SERVICES: Includes foodstuff of all kinds, potable water, and any process where sanitation is a critical concern. Some of the more common applications can be found in sugar refineries, dairy processing, breweries and distilleries.

*Style 120-PB AKⅡ® Vibradamp® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 200 AKⅡ® HYDROPACKING®

-

Description

NEBCO™ Style 200 AKⅡ® Hydropacking® is constructed using white PTFE fluorocarbon fibers blended with a small percentage of aramid fiber with the addition of a lightly colored, and corrosion resistant, reinforcing fiber.

NEBCO™ Style 200 AKⅡ® Hydropacking® is constructed using white PTFE fluorocarbon fibers blended with a small percentage of aramid fiber with the addition of a lightly colored, and corrosion resistant, reinforcing fiber.

The reinforcing fibers are braided in diagonally opposed corners using NEBCO’s™ unique Hydropacking® technology to provide extrusion resistance for pump and valve service.

Initially designed for bleach valves and towers, the chemical inertness provides high speed, non-staining sealing where harsh fluids must be contained. These properties make Style 200 AKⅡ® ideal for sealing valves in chemical, agricultural and petroleum processing industries. -

Specifications

- pH range: 0-14 (except strong oxidizers).

- Surface speeds to: 2,000 FPM (10.1 m/s).

- Pressure to: 2,500 PSI (172 bar).

- Temperatures from: -400°F (-240°C) to 500°F (260°C).

- Abrasion resistant.

- Non-wicking.

- Non-staining.

- PTFE fluorocarbon with aramid fibers and PTFE fiber reinforced Hydropacking®.

-

Applications & Services

APPLICATIONS: Includes rotating pumps, agitators, and mixers, bleach washers, reciprocating metering pumps, chemical injectors, valves and other equipment handling products. Especially suited for sealing valves & knife gates in chemical, agricultural, petroleum processing and waste water treatment industries.

SERVICES: Includes sulfate, sulfite, and NSSC pulping liquors. Air, gasses, oils, solvents, harsh chemicals and paper pulp stocks at any stage.

*Style 200 AKⅡ® Hydropacking® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

NEBCO™ STYLE 200 AF AKⅡ® CHEMSTOP™ VIBRADAMP® HYDROPACKING®

-

Description

NEBCO™ Style 200 AF AKⅡ® Chemstop™ Vibradamp® Hydropacking® is the chemically resilient core version of our Style 200. It is manufactured using white PTFE fluorocarbon fibers blended with a small percentage of aramid fiber with the addition of a lightly colored, and corrosion resistant, reinforcing fiber, with strategically placed AFLAS® cores.

NEBCO™ Style 200 AF AKⅡ® Chemstop™ Vibradamp® Hydropacking® is the chemically resilient core version of our Style 200. It is manufactured using white PTFE fluorocarbon fibers blended with a small percentage of aramid fiber with the addition of a lightly colored, and corrosion resistant, reinforcing fiber, with strategically placed AFLAS® cores.

The reinforcing fibers are braided in diagonally opposed corners using NEBCO’s™ unique Hydropacking® technology to provide extrusion resistance for pump and valve service.

The resilient elastomeric cores and our densely braided ANTI-KEYSTONE® Ⅱ design can help reduce the leakage and gland adjustments where shafts on pumps and other equipment are out-of-round, vibrate or are subject to impact.

AFLAS® is a registered trademark of Asahi Glass Co., Ltd. -

Specifications

- pH range: 1-13 (except strong oxidizers).

- Surface speeds to: 2,000 FPM (10.1 m/s).

- Pressure to: 2,500 PSI (172 bar).

- Temperatures from: -65°F (-53°C) to 400°F (204°C).

- Abrasion resistant.

- Non-wicking.

- Non-staining.

-

Applications & Services

APPLICATIONS: Includes rotating pumps, agitators, and mixers, bleach washers, reciprocating metering pumps, chemical injectors, valves and other equipment handling products. Especially suited for sealing valves & knife gates in chemical, agricultural, petroleum processing and waste water treatment industries.

SERVICES: Includes sulfate, sulfite, and NSSC pulping liquors. Air, gasses, oils, solvents, harsh chemicals and paper pulp stocks at any stage.

*Style 200 AF AKⅡ® should not be used to seal molten alkali metals, solutions containing free halides, or strong oxidizers such as aqua regia, red fuming nitric acid & oleum.

Disclaimer

*Certain styles & sizes are special order only and may be subject to minimum quantities and/or additional terms & conditions.

**For informational purposes only. New England Braiding Co., Inc. (NEBCO™) believes this information to be the best available. Any specific application you have should not be undertaken without independent study and evaluation for suitability, safety and material compatibility. No warranty is expressed or implied as each application is unique. While we have used the utmost care in the preparation of this information, we assume no liability for errors or responsibility for consequential damages resulting from the use of these products.