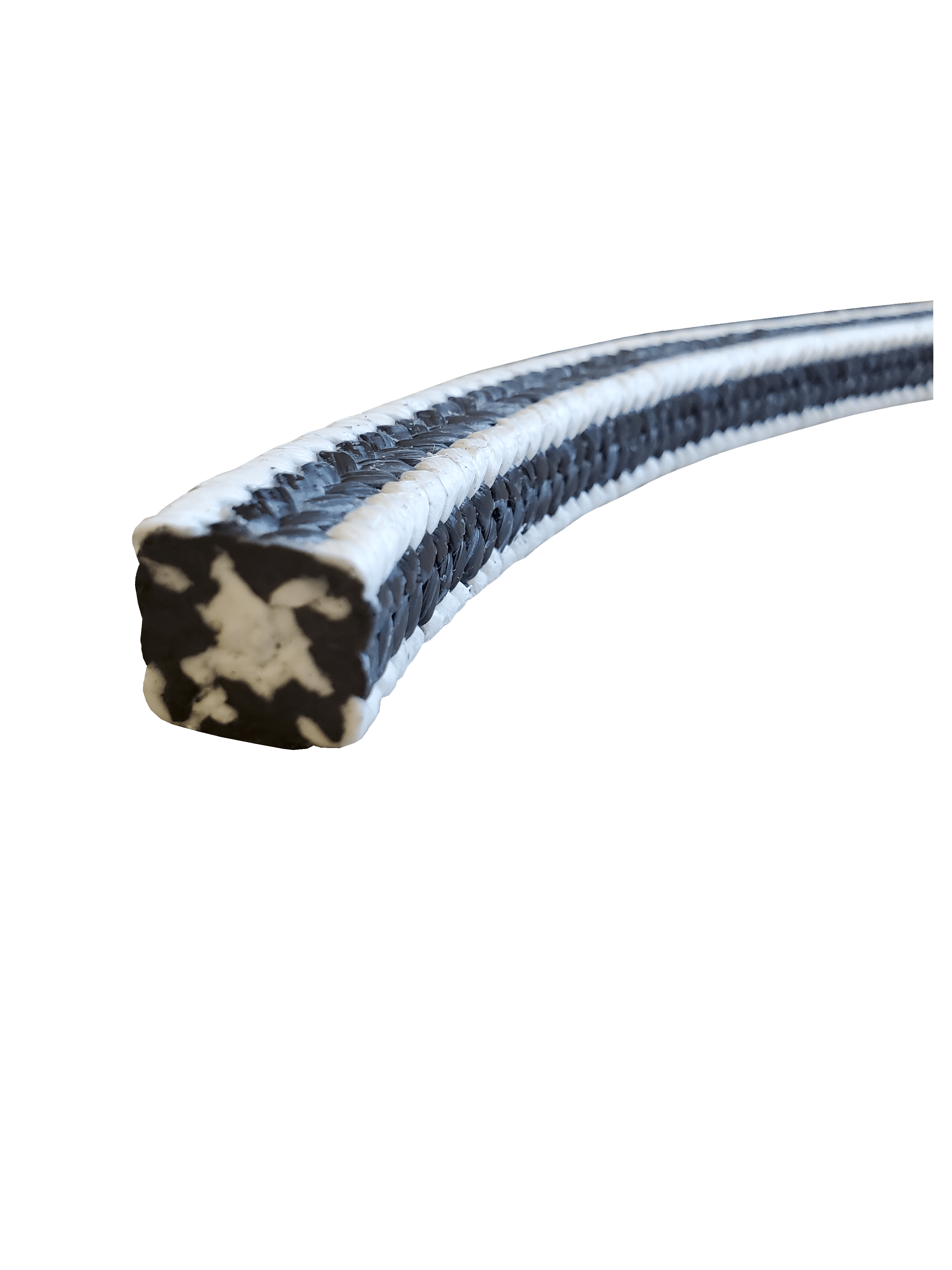

New England Braiding manufactures “Seal Ropes” for specific applications such as Rama Repola washers, where a dense construction with low elongation is required. “Seal Ropes” have large central axial cores buried within the braid to accept the tension placed on the rope. The carefully placed cores prevent the stretching and the resulting reduction in cross section that causes loss of sealing. The diamond shaped cross section readily conforms to the mating V-shaped stationary and rotating sides in these machines.*

NEBCO™ STYLE 102/150 SEAL ROPE

-

Description

NEBCO™ Style 102/150 Seal Rope has a low friction graphite/PTFE composite fiber tightly braided about centrally placed non-stretching cores of para-aramid packing yarn.

NEBCO™ Style 102/150 Seal Rope has a low friction graphite/PTFE composite fiber tightly braided about centrally placed non-stretching cores of para-aramid packing yarn.

The composite fiber in the braid and outer axial fill used in this style provides a conformable sealing surface with the lowest running friction and the greatest rate of heat transfer possible in this non-elongating construction.

Style 102/150 Seal Rope is available in 3/4” and 1” cross sections and in metric cross sections of 20 mm and 25mm. Other sizes are available by special order.

-

Specification

- pH range: 0-14.

- Surface speeds to: 3,000 FPM (15.2 m/s).

- Pressures to: 250 PSI (17 bar).

- Temperatures to: 500°F (260°C).

-

Applications & Services

For specific applications such a Rama Repola washers, where a dense construction with low elongation is required. The diamond shaped cross section readily conforms to the mating vee shaped stationary and rotating sides used in these machines.

NEBCO™ STYLE 6902 SEAL ROPE

-

Description

NEBCO™ Style 6902 Seal Rope is manufactured from a low friction PTFE/graphite composite fiber with extrusion resisting corners of expanded PTFE tightly braided about centrally placed non-stretching cores of expanded PTFE packing yarn used axially.

NEBCO™ Style 6902 Seal Rope is manufactured from a low friction PTFE/graphite composite fiber with extrusion resisting corners of expanded PTFE tightly braided about centrally placed non-stretching cores of expanded PTFE packing yarn used axially.

Style 6902 Seal Rope is available in 3/4” and 1” cross sections and in metric cross sections of 20 mm and 25mm. Other sizes are available by special order. -

Specification

- pH range: 0-14.

- Surface speeds to: 1,200 FPM (6 m/s).

- Pressure to: 1,000 PSI (68.9 bar).

- Temperatures to: 500°F (260°C).

-

Applications & Services

For specific applications such a Rama Repola washers, where a dense construction with low elongation is required. The diamond shaped cross section readily conforms to the mating vee shaped stationary and rotating sides used in these machines. Style 6902 is useful in all types of brown stock and bleach washers.

*Please note that there is also an Acrylic/Aramid Seal Rope Style 4200 available. Please contact New England Braiding Co., Inc. for details.

Disclaimer

*Certain styles & sizes are special order only and may be subject to minimum quantities and/or additional terms & conditions.

**For informational purposes only. New England Braiding Co., Inc. (NEBCO™) believes this information to be the best available. Any specific application you have should not be undertaken without independent study and evaluation for suitability, safety and material compatibility. No warranty is expressed or implied as each application is unique. While we have used the utmost care in the preparation of this information, we assume no liability for errors or responsibility for consequential damages resulting from the use of these products.